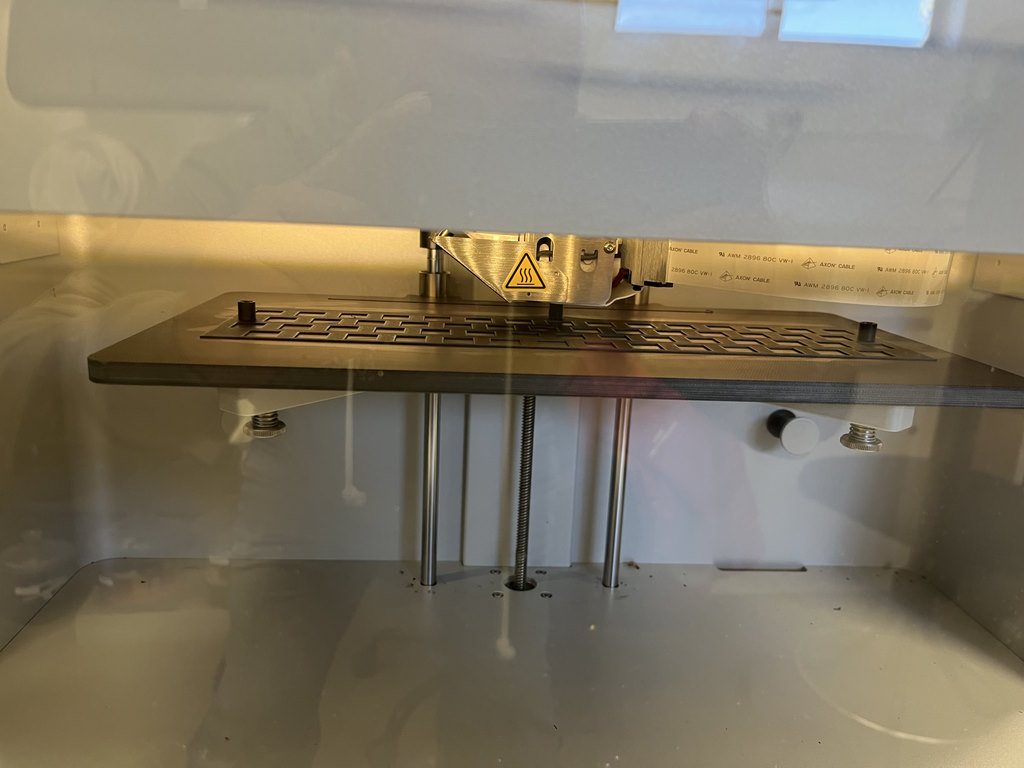

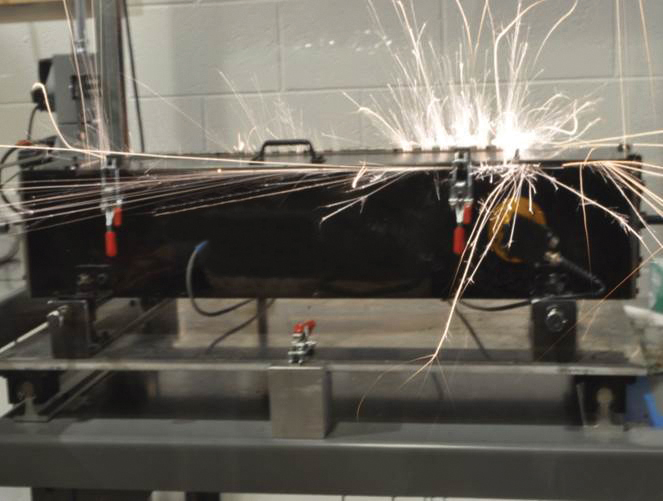

From reactive metal powders and fragments, cast cure and melt cast reactive liners, 3D printed liners and molds, to impact ignition and full arena testing, RMII strives to deliver enhanced performance for the propellant, ordnance and pyrotechnics community.

R&D and Production Services

- Custom Reactive Material Design

- Mechanical Milling

- Hot Milling

- Dry Blending

- Electrostatic Precipitation

- Development of Reactive Material/Binder Combinations

high-speed optical and x-ray imaging, and vented-chamber calorimetry for combustion analysis.

Reactive metal and self-oxidizing reactive composite systems

- Gram to kilogram quantities available

- Custom consolidation of composite powders

In house analytical capabilities include:

- Impact initiated combustion efficiency

- BET surface area

- SEM

- ESD

- DSC

- FTIR

- Pycnometer

- Calorimetry

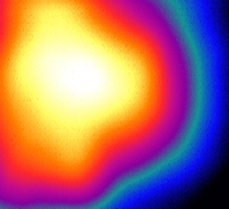

- Thermal Imaging

- BAM Friction

- Drop Tests